While some might not recognize the importance of Triethylene Glycol Regenerative Gas Dehydration systems, professionals in the oil and gas industry understand the crucial role in production. Additionally, their care and maintenance is a process that is quite detailed and a highly specialized area of service.

GLY-TECH entered the service area in 1986 and has come to be known as true artists when it comes to servicing gas dehydrations systems through the course of their business. Harnessing 35 years of experience to date, GLY-TECH can service these systems and develop a training school to pass this knowledge to a variety of industry personnel, including anyone involved in operating glycol system equipment, newly hired engineers, production supervisors, as well as safety management personnel. GLY-TECH’s industry-recognized training school came to fruition over twenty years ago and has since premiered as the ultimate 2-day gas dehydration training around.

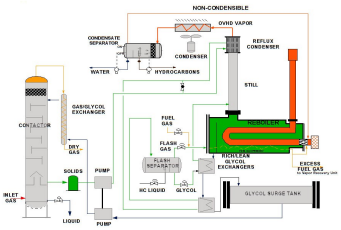

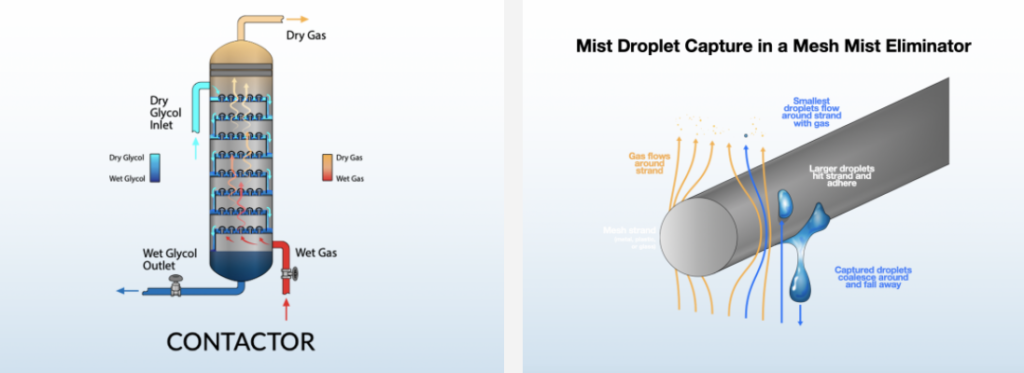

To grasp the importance of such a class, a proper understanding of gas dehydration should be clear. According to Douglas Daigle, GLY-TECH instructor, gas dehydration is the process of removing water vapor from gas to prevent hydrates from compacting pipeline pressure and plugging pipelines.

“The process increases pipeline efficiency and reduces corrosion damage,” said Daigle. “Ultimately, dehydration increases the BTU of the gas.”

Setting Goals

With a focus on increasing efficiency and reducing damage, it is evident that gas dehydration saves money, allowing for increased profit margins and redirection of expenditures. GLY-TECH’s course instructors promote seven feature goals:

- Increasing safety awareness

- Prevention unscheduled shut-ins

- Reduction in system operating costs

- Increasing system operating efficiency

- Reducing unnecessary glycol loss

- Learning simple troubleshooting techniques

- Understanding the importance of proactive maintenance programs

Course Objectives

GLY-TECH’s gas dehydration training course is designed to accomplish these goals through a series of objectives. Through the two-day sequence, students received education on the following:

- Increased employee effectiveness

- Decreased cost of operations

- Substantial financial benefits

These conditions and applications have been tested, and a vast industry experience only validates that they are effective in the field and ultimately reduce damage and increase efficiency. GLY-TECH’s customers have reported cost savings of up to 50 percent due to their employees’ new awareness of proper startup and operating procedures, as well as the attention directed at maintenance programs and safety awareness.

“This is one of the best schools I’ve ever attended that deals with glycol systems on an operator’s level,” said Ron Bayless of Performance Energy Services.

Tricks of the Trade

It is no secret that there is a great deal of information to understand and process when it comes to gas dehydration and glycol operating systems. While a two-day course might not seem adequate, GLY-TECH has streamlined the process to deliver the most critical information during the course’s duration. It understands the need for process professionals to be in the field managing their systems.

GLY-TECH instructors focus on specific methods to accomplish the course’s goals and meet the objectives. One proven method is identifying the three factors to a lower dew point depression. Dew point is the temperature at which a component such as natural gas will begin condensing out of the gaseous phase. It is dependent upon the composition and pressure of the gas.

With the gas being the source of income, the dew point must be lowered to reduce the condensing, effectively the loss of sellable gas. GLY-TECH’s course provides a proper countermeasure that can prevent this occurrence.

“Lowering dew point can be accomplished by monitoring the operating conditions and limits of the dehydration system. Temperature, pressure, liquid levels, and flow rate must be righted where needed,” said Daigle. “The upstream gas directed to the contact tower must be controlled.”

After establishing the working parameters of the system to accomplish a lower dew point, there is still work to be done. The parameters must be maintained to thrive with consistency.

“Companies must maintain the five fine points of a proactive preventative maintenance program,” said Daigle. “Recordkeeping and mechanical maintenance are essential along with glycol care, corrosion control, and good communications.”

GLY-TECH employs a knowledgeable staff that can assist with these parameters even after individuals complete the training course. With a plethora of products and services, GLY-TECH can guide customers to successfully managing their gas dehydration systems and maximizing profits along the way.